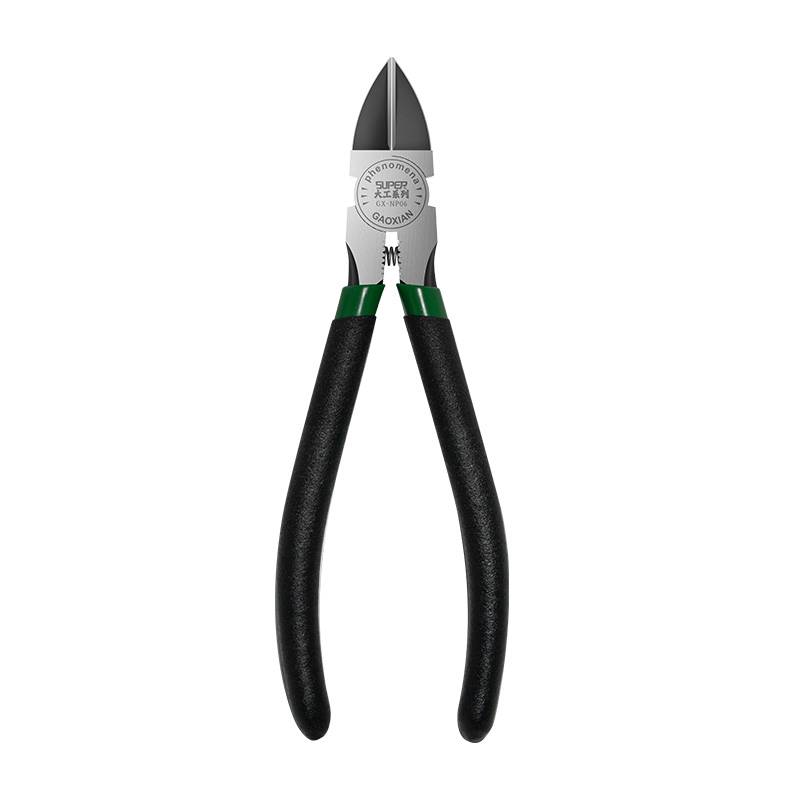

GX-NP06

Overview

This plier is for cutting various types of cables in construction; it is applicable to cable types including round/elliptical category 3 cables, category 5e cables, category 6 cables, and category 6a cables, as well as cutting soft materials like plastic.

Material

The entire cutter is made of chrome-vanadium steel, which has a better combination of strength and toughness than carbon steel, making it suitable as a high-quality tool material. After heat treatment, its hardness exceeds 60 HRC (Rockwell hardness), providing excellent wear resistance.

Standard Compliance

GB/T 6290-2013

Quality Assurance

1 year warranty

Specifications

| Model no. | GX-NP06 |

| Product Type | Cutting Plier |

| Blade | Crafted with CNC equipment, ensuring a smooth blade edge. Single-blade structure, offering better cutting force and durability for soft materials. |

| Coating | PVC Dip Coating |

| Standard Compliance | GB/T 6290-2013 |

| Quality Warranty | 1 year warranty |

Packaging Detail

| Std. Qty | 1 pcs |

| Size | 11mm*52mm*160mm |

Born to cut wire

Single blade structure

The blade is a single-blade structure, through the NC equipment processing molding, better shear toughness and impact resistance.

Maintenance

- Upon unpacking, check whether the corresponding parts of the product have been coated with rust-proof oil;

- During use, try to avoid letting the tool come into contact with liquids (such as sweat, water, beverages, etc.);

- During high-altitude operations, make every effort to protect the tool from falling;

- If conditions allow, you should regularly apply rust-proof oil to the tool;

- After using the tool, it should be placed in a protective environment such as a toolbox.

Non-slip Handle

PVC material, more comfortable, not falling off

Double PVC dip sheath, the inner layer for the smooth surface, the outer layer for matte surface, anti-slip comfortable;

Dipping process: the handle is immersed in the rubber compound under the adjusted molten state,

according to the thickness of the sheath, it is soaked for a corresponding time and then taken out. The soaked plastic can adhere along the outer wall of the product,

there is a tendency to shrink the handle close to the blade end, further ensuring that the sheath does not fall off: